The term plastic is used frequently in society, as it seems nearly everything is made of it- including our clothes!

While most consumers are familiar with what plastic is, the relationship between plastic and materials like polyester and PET on labels and packaging is generally less known.

While these three terms can be interchangeable to an extent, there are differences between them. To continue to educate our community, we’ve decided to explain the similarities and differences between these material names and how they relate to our products!

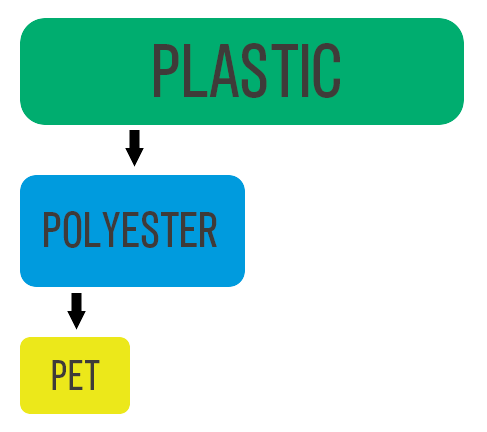

Plastic: Plastic refers to synthetic or semi-synthetic materials that are pliable and moldable because they are made of polymers. Polymers are large chain-like molecules, made of repeating units; this feature is what allows us to make endless shapes and products with plastic. Overall, plastic is an umbrella term that encompasses many different types of polymer materials.

Polyester: Of the different types of plastic polymers, one of the most popular categories is called polyester. Polyester is a smaller umbrella term that encompasses a narrower range of plastics categorized by the esters in their repeating polymer chain units- hence the name polyester, meaning “many esters.”

PET: Of the different types of polyester, PET (Polyethylene Terephthalate) is the most commonly manufactured. It is inexpensive, strong yet lightweight, naturally colorless, and water-resistant. The raw materials for PET are usually derived from petroleum or natural gas and the final product is used mostly to make plastic bottles, food packaging, and textile fibers.

To make the complicated simple: PET is a type of polyester, and polyester is a type of plastic!

How is Recycled PET used by Recover?

The high thermoplasticity (ability to melt and reform) of PET is what makes it possible to transform old PET bottles into new fabric! By melting down the plastic material, we can extrude it through a plate with fine holes, known as a spinneret, and then rapidly cool it to solidify it into fibers.

This fiber-forming process is called melt spinning and the new material is called recycled PET (also known as rPET)!

These fibers are then knit into fabric and, eventually, turned into clothing. We utilize recycled PET fiber in our Eco, Classic, Fleece, Sport, and Sport Elite collections- as well as our new Impact Jacket!

By using recycled PET, we are able to reuse plastic that already exists within our environment and keep it out of landfills and waterways, while reducing the need to extract resources like petroleum to create new PET.

This sustainable process is just one of many examples of how we are delivering on our mission to "Help Earth Recover".