A few weeks ago, we went down to Guatemala to visit our manufacturing partner’s production plant. The trip allowed us to spend some time with all the folks there, check quality control on current production and working conditions, and initiate the development of some new products. It was an action-packed week that left our team excited about a number of great things ahead. For starters, our partners were very enthusiastic about advancements in our current product line. The technology of making a 100% recycled garment just keeps getting better, and we’re thrilled to see the style, comfort and durability of our products continually improving. It was also very encouraging to explore the potential of product development. We’ll elaborate more on that in the near future, but for now we wanted to share some photo highlights from the trip and give you a look inside their state-of-the-art facilities.

This is a knitting machine in action. During the early stages of our process, plastic bottles and cotton scraps are collected, broken down and blended into yarn that is then knitted into fabric to make our products.

Normally, knitted fabric goes to a dye-house like this one, where it is dyed and finished. This step requires a tremendous amount of water and energy. We don’t use any dyes when making our 50/50 products. The vibrant colors come from recycled cotton scraps. This saves roughly 9-times the amount of water used to make a shirt that is dyed via conventional methods.

The colors in our Recover Dry products are the result an over-dye, which we have determined to be the most environmentally way to add color to that product. The dyeing is performed with Green Label certified machines specifically designed to minimize the use of water, chemicals, and energy.

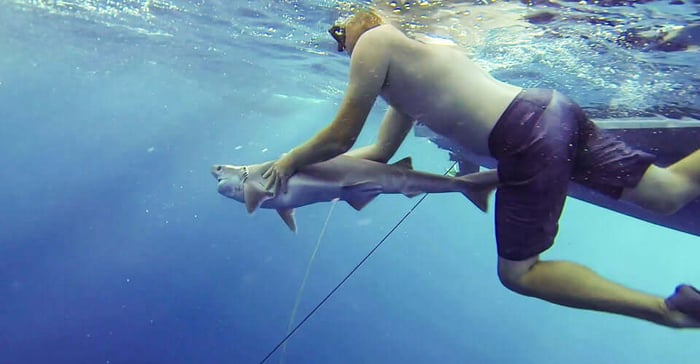

The cut and sew factory is where a Recover garment really comes to life. Once the recycled materials have been processed into new fabric, the cloth is sewn into the shirt or hoodie that you end up wearing on a daily basis. This step requires great attention to detail and a very skilled workforce. These operators are are extremely focused on sewing the garment to its exact specifications.

The facility in Guatemala is powered by 100% clean biomass that consists of wood chips, coffee extract, and other materials. These wood chips are collected from the local forestry industry.