At Recover, we are driven by a commitment to holistic sustainability, integrating environmentally and socially responsible practices into every aspect of our production. From the materials we use, to our supply chain operations, to our apparel recycling program, we are dedicated to making the biggest positive impact possible through sustainable apparel.

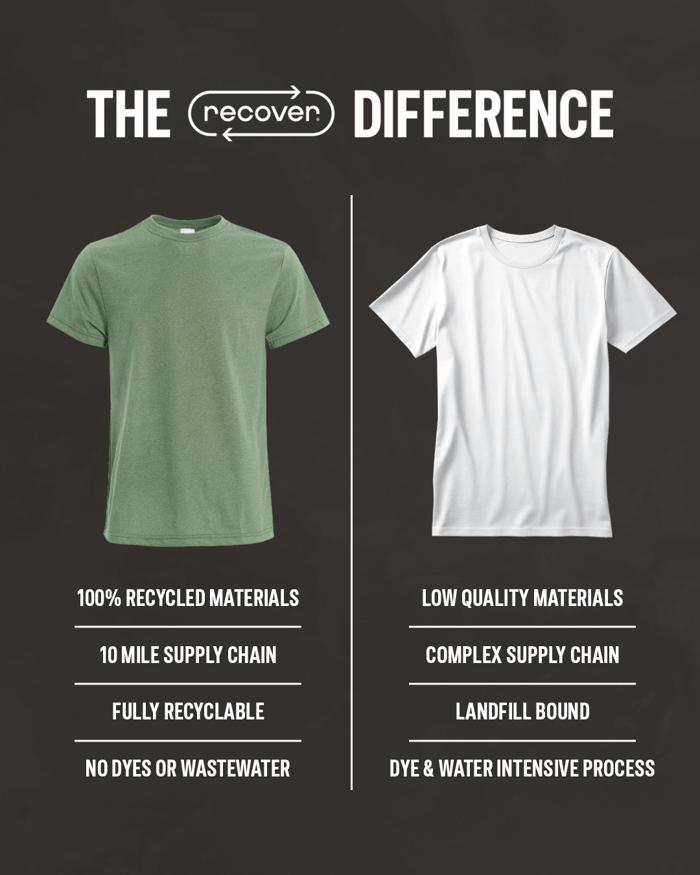

The Recover Difference represents our journey to be innovative in incorporating sustainability, ensuring that is not just a part of what we do, but the foundation of what we do.

The apparel industry mostly relies on virgin (newly extracted) synthetic materials, such as polyester, which are often produced from petroleum-based chemicals.

Though these fibers are the most commonly used, the significantly increased production of new plastic fibers over the years raises environmental concerns, including fossil fuel extraction and long-lasting polyester waste.

Cotton is another commonly used material in the apparel industry. Despite being a natural fiber, it is not without its environmental downsides either. Although cotton farms occupy just 3% of the world’s arable land, they are responsible for 4.7% of global pesticide sales, and 10% of global insecticide sales, and require an estimated 8 million tonnes of fertilizers each year. The heavy reliance on pesticides, insecticides, and fertilizers can lead to severe environmental issues such as contaminated soil and polluted water.

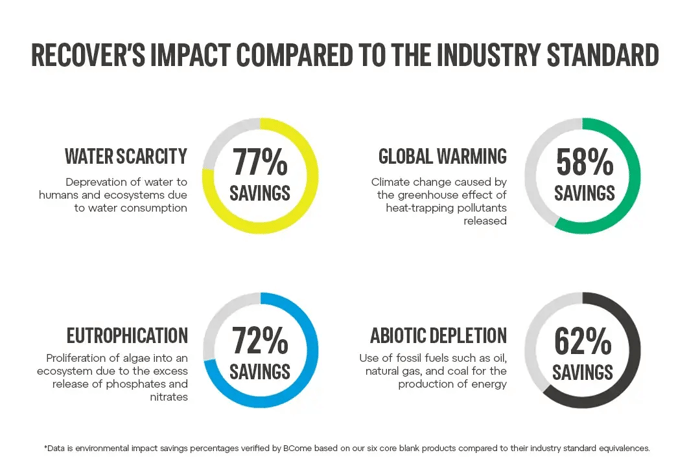

To tackle these environmental challenges relating to materials in the apparel industry, Recover prioritizes low-waste materials to minimize environmental impact. We utilize 100% recycled polyester and 100% recycled cotton, both certified through the Recycled Claim Standard 100 and Global Recycled Standard to ensure traceability and verified recycled material content.

By recycling already existing materials and converting them into new fiber for apparel, we are able to keep waste out of landfills, prevent virgin material production, and conserve valuable resources. This process reduces water, energy, and land use while limiting greenhouse house emissions.

Additionally, we use 100% US-grown organic cotton that is USDA certified. By choosing organic cotton for our Organic Cotton Tee, we avoid the use of harmful pesticides, insecticides and fertilizers that negatively affect animal biodiversity, water supplies, and human health.

By using sustainable textile material alternatives we have reduced our impact, and by working with BCome, a platform for global sustainability management, we have been able to quantify that impact.

You can learn more about our materials HERE and our certifications and verifications HERE.

In addition to relying on unsustainable materials like virgin polyester, many apparel companies outsource production to overseas manufacturers where labor costs are lower and environmental protections are less stringent.

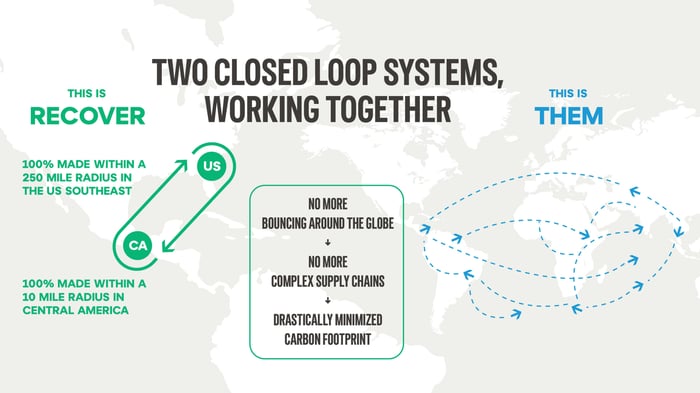

This complex global supply chain also plays a major role in contributing to greenhouse gas emissions, as clothes often undergo lengthy and unnecessary transportation where they are flown or shipped around the globe for each step of their supply chain. Your average t-shirt can easily travel 17,000 miles during its production.

Our HyperLocalTM supply chain is only a small fraction of that distance! It is a unique sustainable manufacturing approach that places emphasis on utilizing more efficient, locally-based supply chains.

Our US Supply chain operates within a 250-mile radius in the U.S. Southeast, while our El Salvador supply chain features vertically integrated production all confined within a 10-mile radius. Nearshoring operations allows us to significantly limit CO2 emissions associated with supply chain transportation- by 93% to be exact!

To further our sustainability efforts, our production facility in El Salvador harnesses solar power, with 37% of the energy used coming from on-site generated solar power, and 75% of the energy used coming from renewable sources overall. Our El Salvador facility additionally recycles up to 60% of the water used during manufacturing, helping to reduce water consumption.

Our U.S. Southeast supply chain continues to support the textile-rich heritage of our home region and the communities that are at its core. Through this, Recover has been able to create demand for textile jobs in small towns across the southeast and for the production of recycled textile materials at home.

You can learn more about our supply chain traceability HERE and our HyperLocalTM supply chain HERE.

Another significant concern in the apparel and textile industry is the growing clothing waste, driven by a shift towards a single-use economy.

To put the textile waste crisis into perspective… in 2018, the United States generated 17.03 million tons of textiles, landfilled 11.3 million tons, combusted 3.22 million tons, and recycled 2.51 million tons.

As noted, synthetic fibers now dominate the global fiber and textile market. As the production of these new synthetic textiles, along with textiles in general, continued to grow year after year, there appeared to be no plan to keep these materials circulating within the supply chain.

While many companies continue to produce items that inevitably contribute to this waste, we are committed to doing things differently by incorporating circularity into our supply chain to help tackle the clothing waste crisis.

To combat end-of-life waste, we prioritize the recyclability of clothing through our 360° Closed Loop Program. This initiative works on both a large scale with our wholesale partners through inventory takeback and large event activations, as well as individually with our online customers, where they are able to send back old items using our pre-labeled Closed Loop mailers.

In 2024, we were able to divert 4,977 lbs of apparel waste from entering the landfill through our 360° Closed Loop Program.

Beyond sourcing recycled materials for our products, we are able to actively collect old or unused T-shirts from both customers and wholesale partners. Rather than allowing these garments to end up in landfills where they will take up to 200 years to break down, we repurpose them by transforming them into new materials. By integrating this practice into our operations, we strive to help close the loop on textile waste, ensuring that products can contribute to a more sustainable future through a longer life cycle.

Outside of our sustainable production initiatives, Recover is deeply committed to giving back to the environment through our partnerships with various environmental organizations. We’re proud to be a longtime member of 1% For The Planet. Earlier in 2024, we celebrated a significant milestone, having donated over $250K to initiatives helping our planet. These contributions support a wide range of projects from the global to local level, working to conserve, preserve, and protect our planet for future generations.

Through our comprehensive commitment to sustainability, Recover aims to provide not only high-quality products that meet the needs of our customers but also products that make a positive impact. By highlighting what sets us apart and continuously innovating in sustainable apparel, we strive to maintain our position as a true leader in the industry.